Technology

JP-PROLAK a.s.

Opatov 183, Czech Republic

info@prolak.cz

Laser Cutting

One of our latest available technologies:

In continuous production we process metal sheets:

Steel in thickness 0,5 - 25 mm

Stainless in thickness 0,5 - 20 mm

Aluminium in thickness 0,5-8mm

Sheet format 4000 x 2000 mm

Available machinery:

- BYSTRONIC BySmart Fiber

- BYSTRONIC ByStar Fiber 6kW

Laser 3D cutting

One of our newest technologies.

We process profiles in continuous operation

and pipes up to a circumscribed circle of 130 mm

Available machinery:

- BYSTRONIC ByTube 130

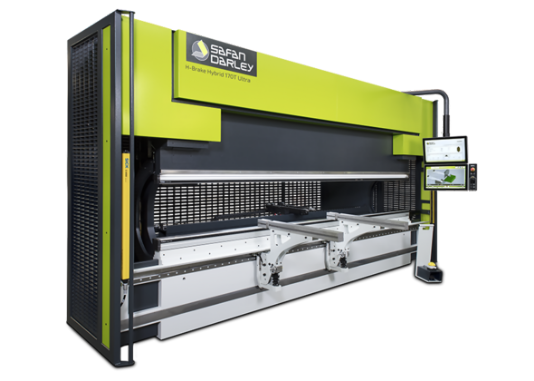

Bend sheet metal

In three shifts, the cut sheets are bent on our SAFAN CNC bending presses according to customer drawings.

Machines:

- SafanDarley E-Brake B100-3100

- Safan E-Brake 35-1250

- SafanDarley H-Brake Hybrid E-Control 170.42/37

- CNC circular machine DAVI MCA2019

- Bystronic Xpert Pro 200

- Bystronic bending robot workstation

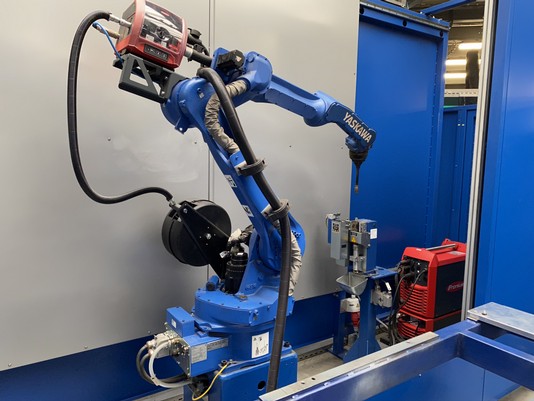

Welding

In order to make our range of services as broad as possible, we offer our customers the assembly of components by welding using MIG and TIG technologies

In production we also use welding robots with three separate workstations

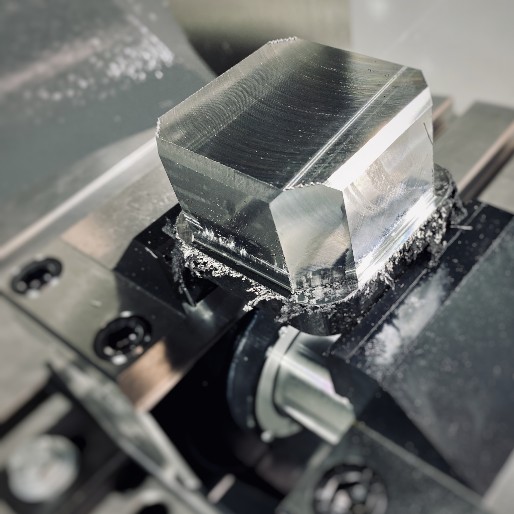

Machining

To complete our processing range, precision parts are manufactured on manual and CNC milling and lathe machines.

Machinery:

- CNC lathe HASS ST-25

- CNC lathe HASS TL-2

- CNC lathe HASS DS-30Y

- CNC milling machine HASS VF-4

- CNC milling machine HASS SMIMIMILL 2

- CNC milling machine HASS UMC-1000SS

- CNC saw KALTENBACH KKS 461 NA

Powder paintline

In continuous production we are painting the parts with powder-paint in two options – static and TRIBO. Phosphating the parts and passivation is an obviousness.

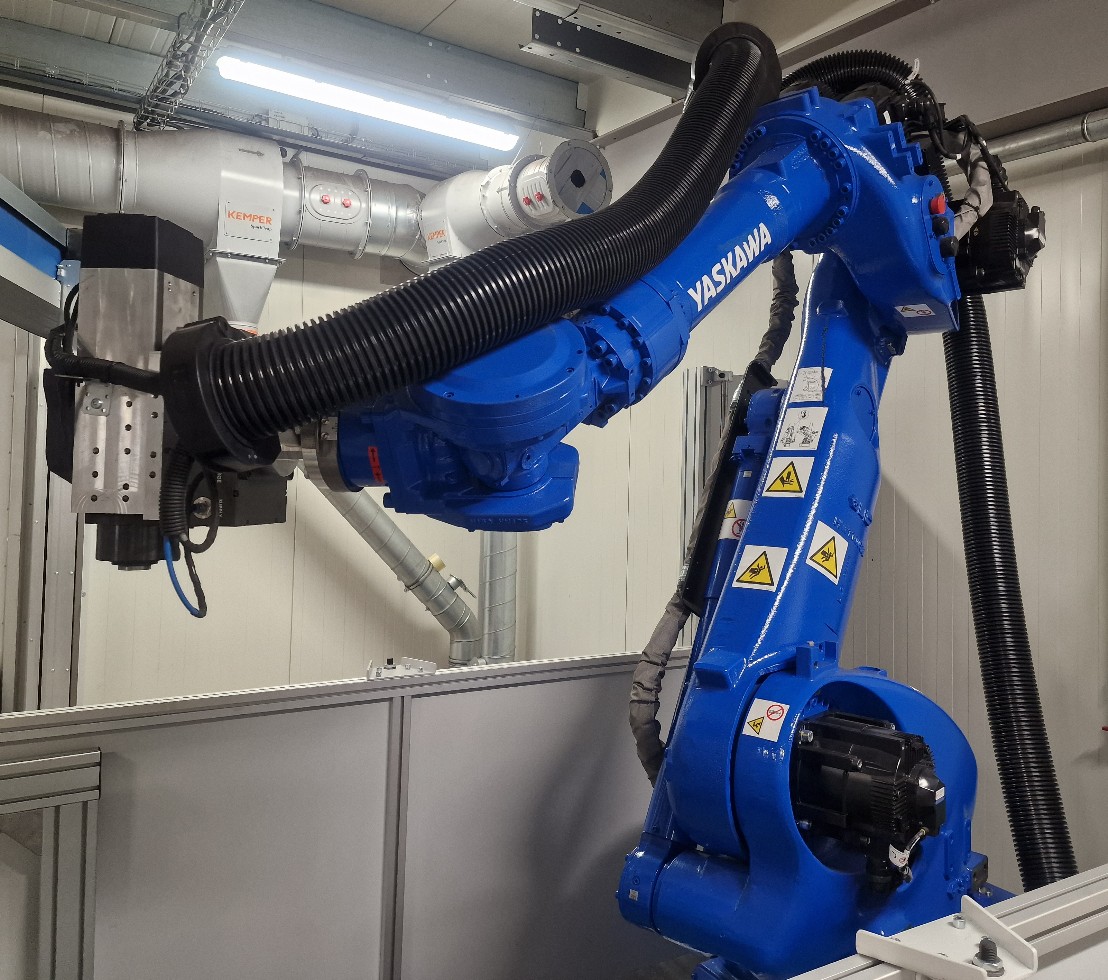

Finishing the product

For the surface treatment of metal parts, we can offer our customers surface belt grinding, sanding (brushing) and sandblasting. We grind the visible surfaces manually, but now also use an automatic workstation equipped with a robot.

JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating, JP-Prolak, laser, Laser cutting, Metal sheet folding, Welding, Machining, Milling, Turning, powder coating,lakovna, svařování, obrábění