Production and technology

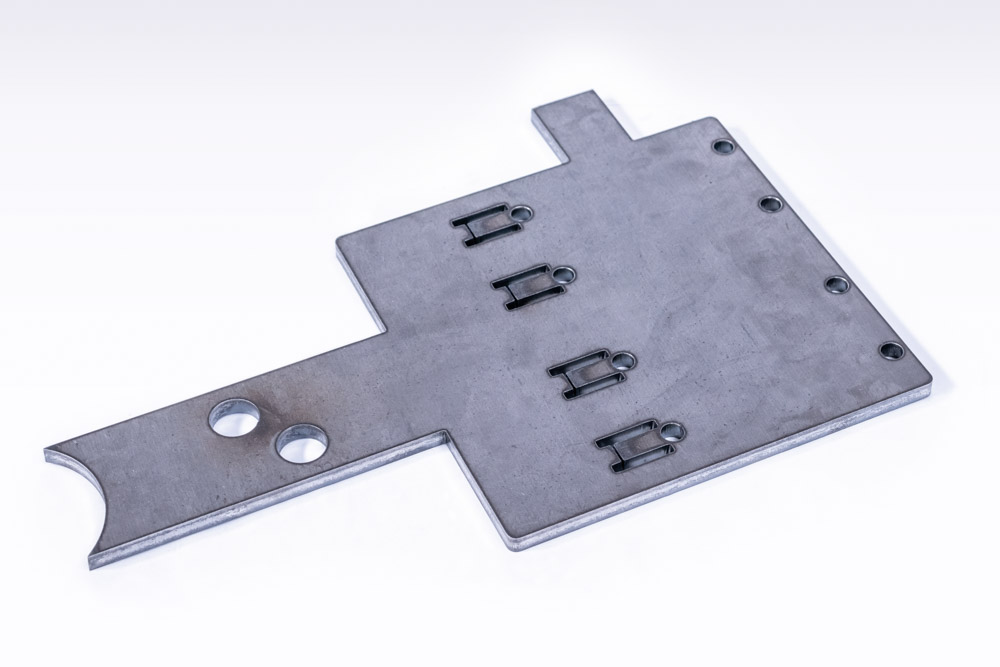

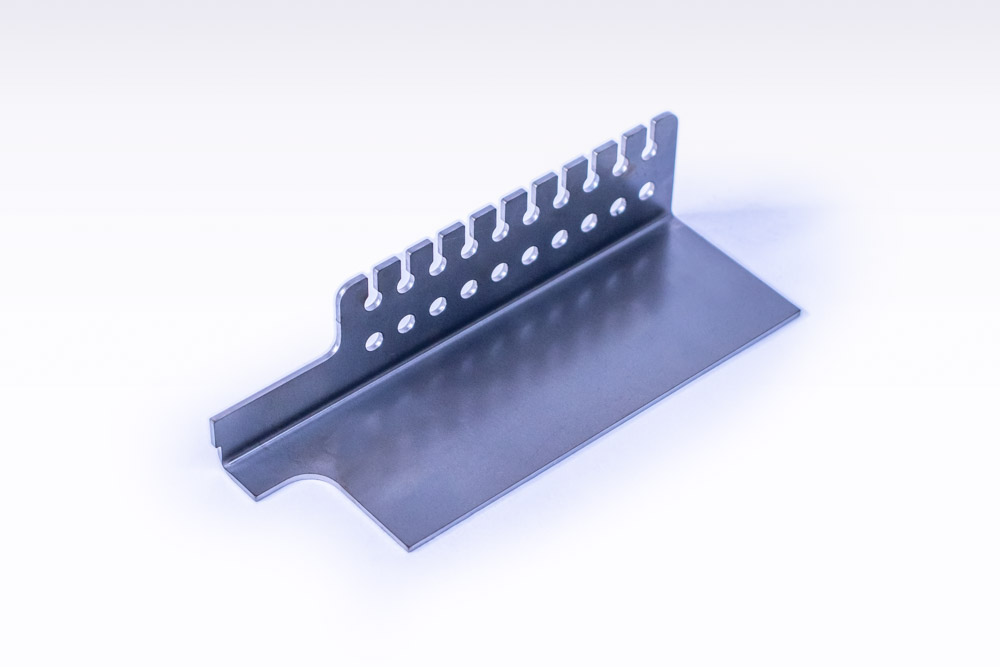

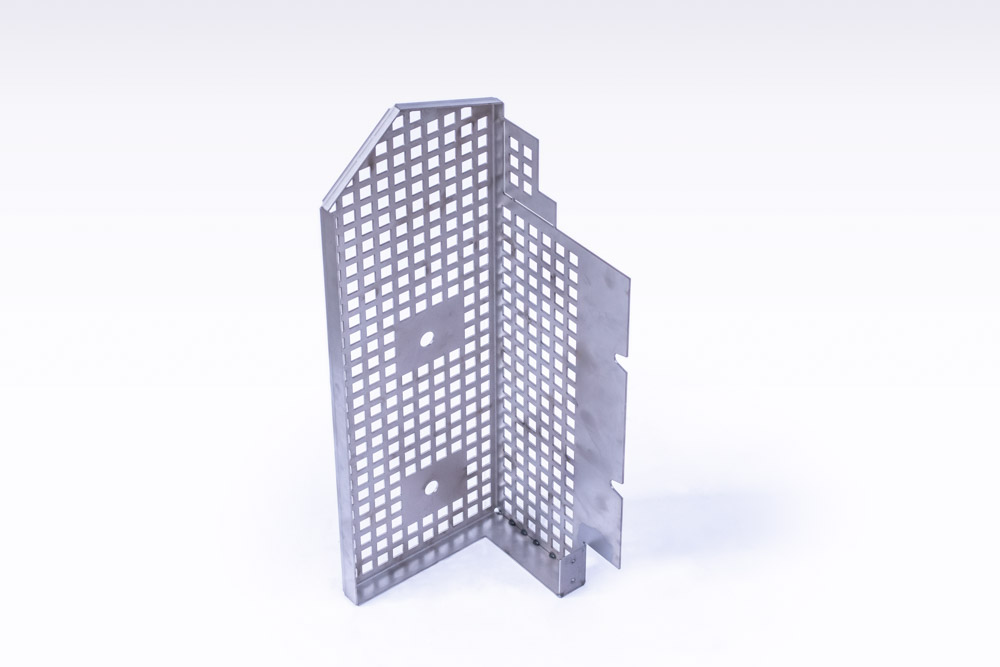

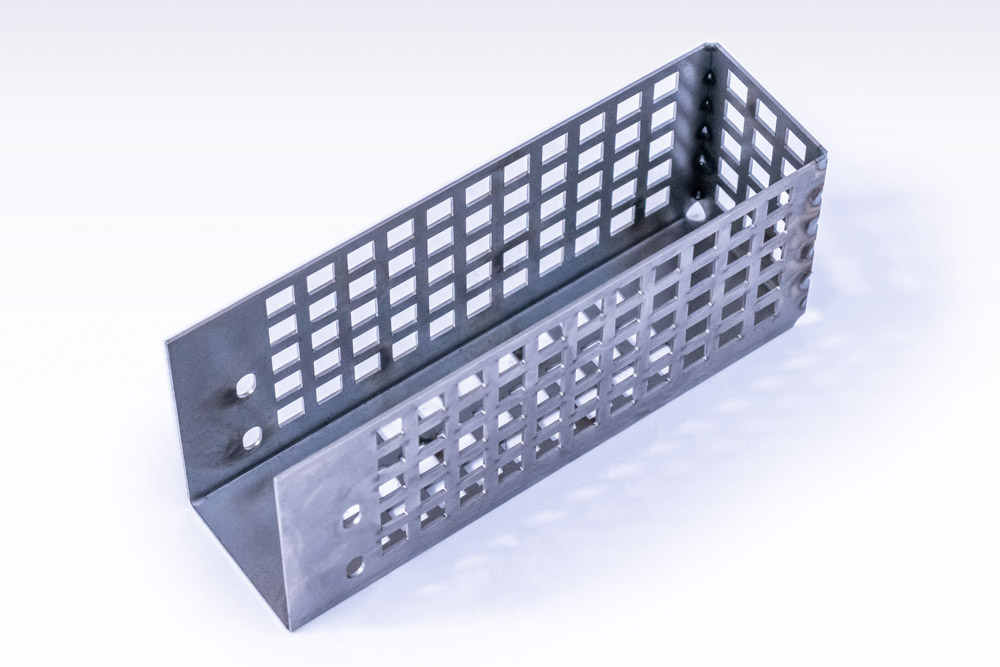

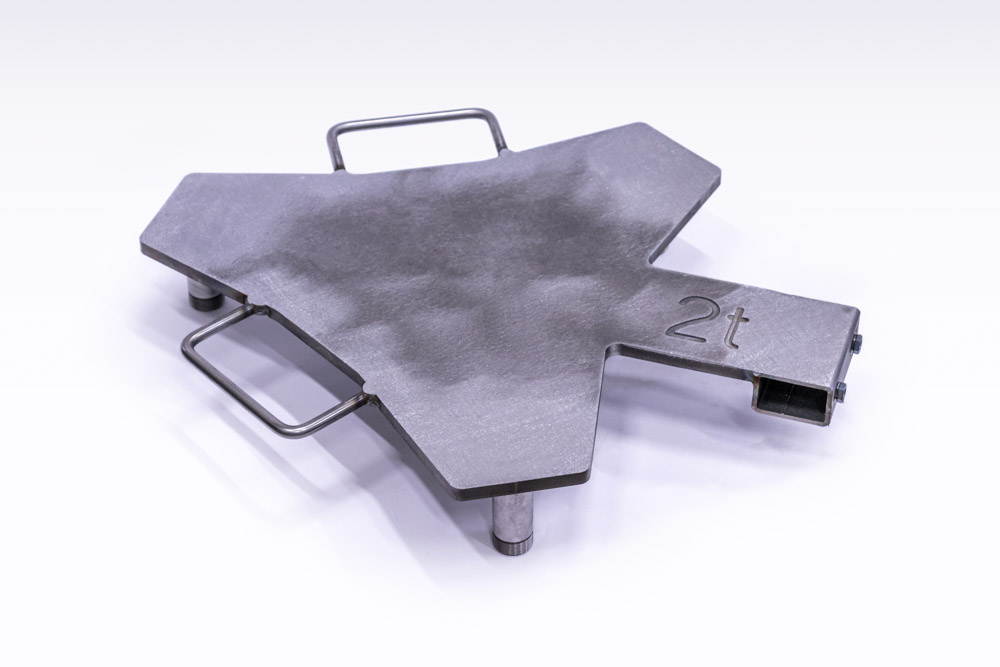

Laser sheet metal cutting

The plant’s advanced technologies include a continuous sheet metal processing line, enabling us to efficiently and precisely process sheet metal of various thicknesses:

Steel 0.5-25 mm

Stainless steel 0.5-20 mm

Aluminium 0.5-8 mm

Stainless steel 0.5-20 mm

Aluminium 0.5-8 mm

Sizes up to 4,000 × 2,000 mm

Machinery:

BYSTRONIC BySmart Fiber

BYSTRONIC ByStar Fiber 6kW

BYSTRONIC BySmart Fiber

BYSTRONIC ByStar Fiber 6kW

View gallery

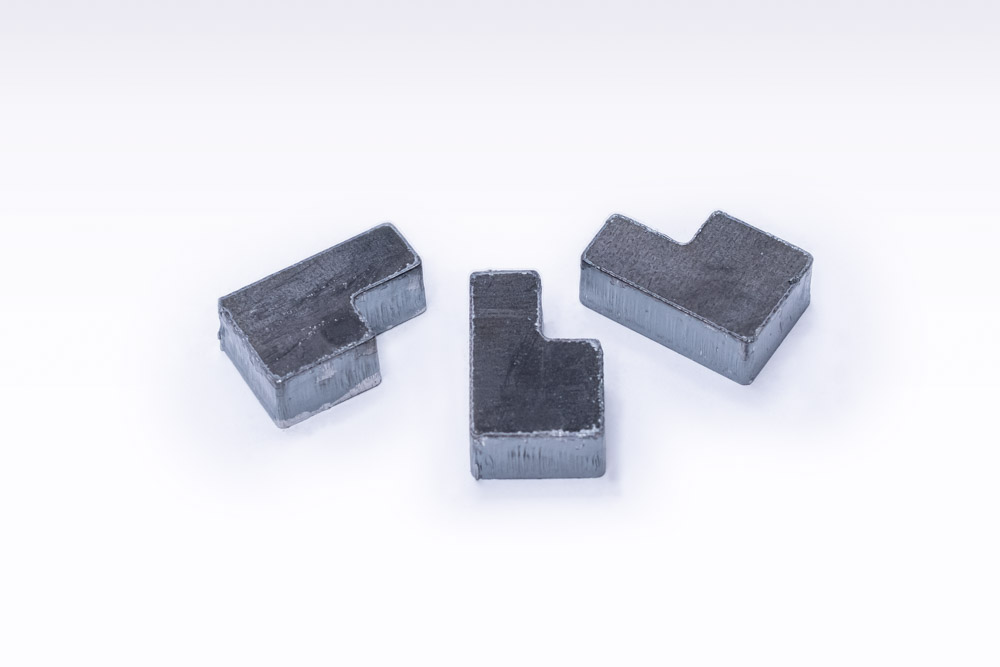

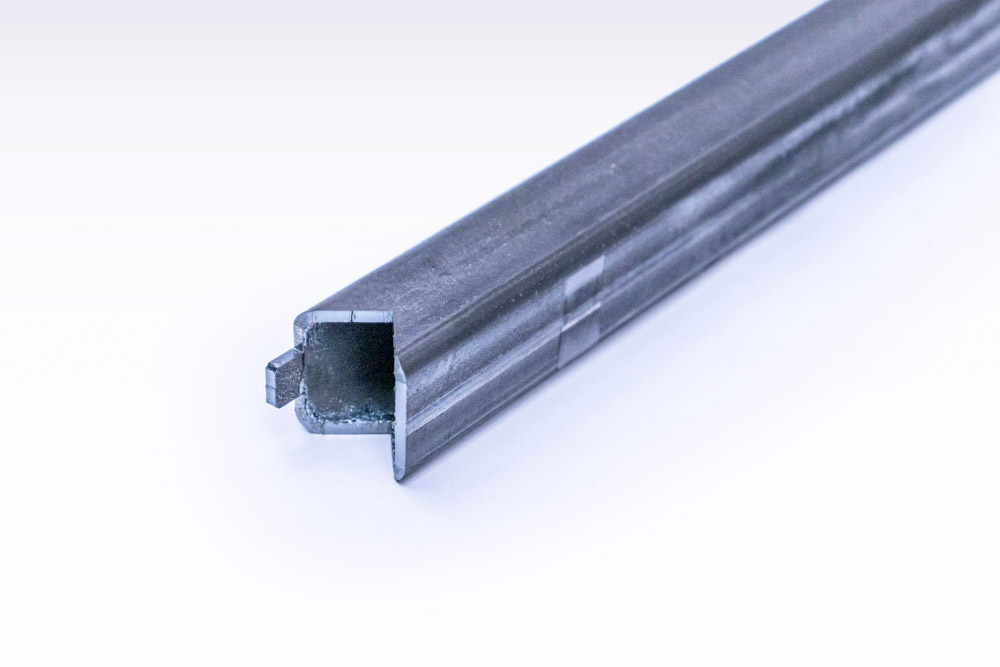

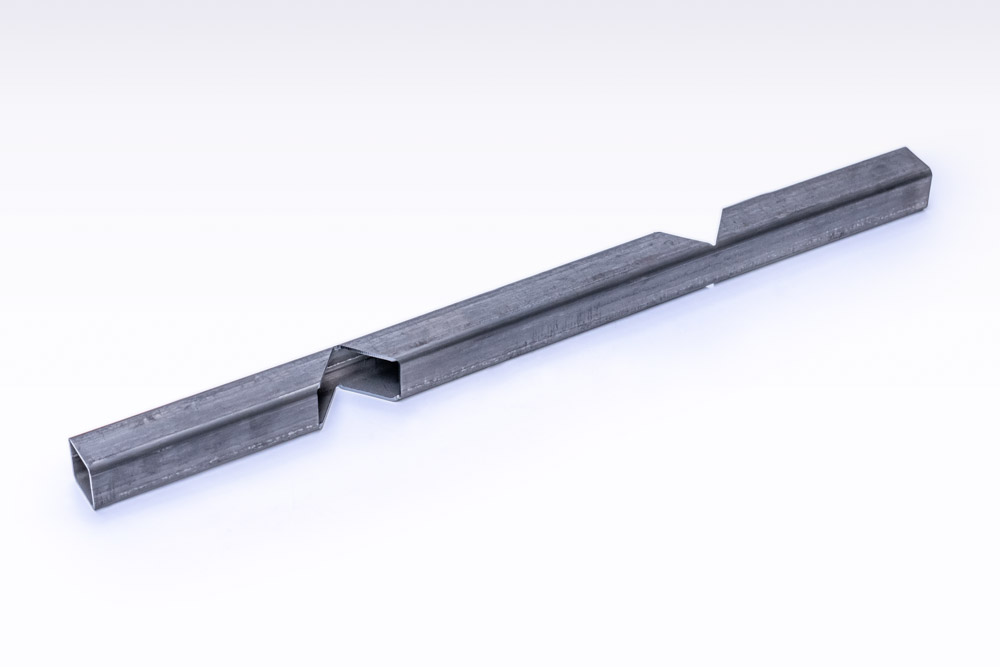

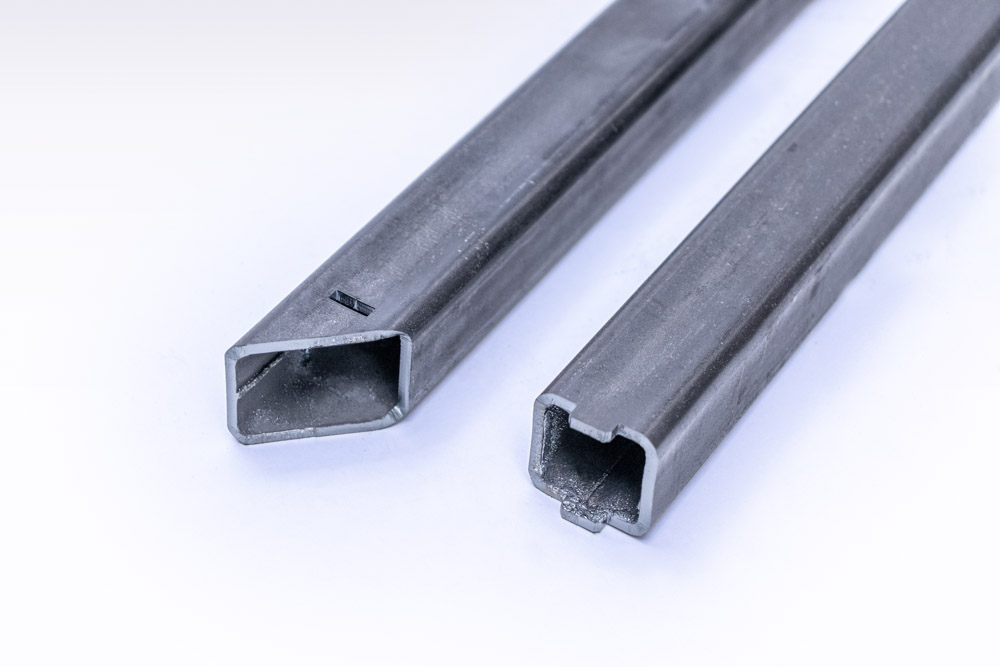

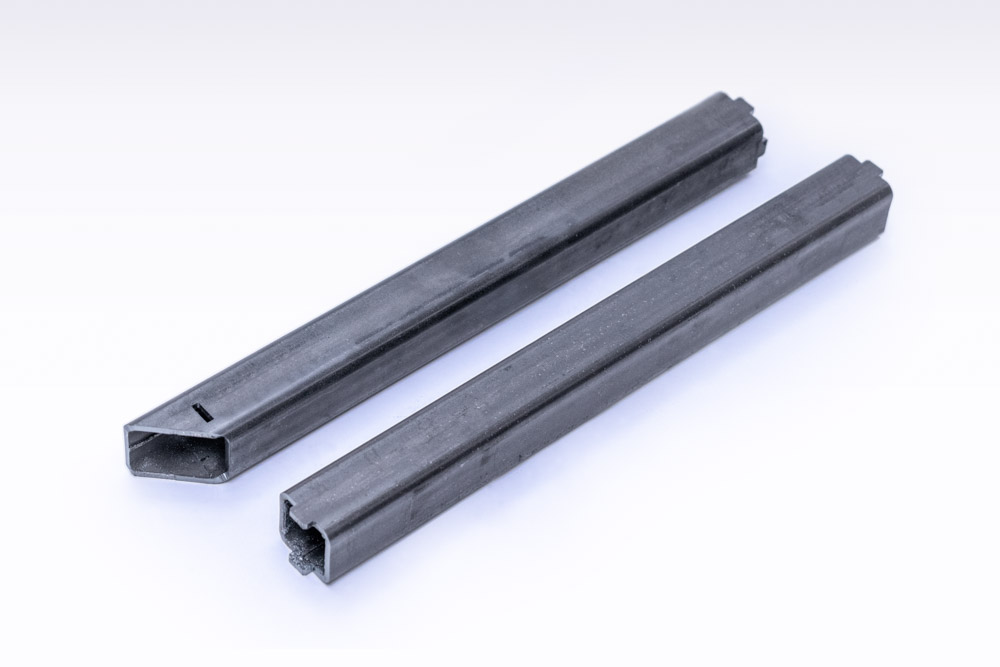

Laser 3D cutting

Our advanced technologies include a continuous line for the processing of profiles and tubes, allowing us to achieve high efficiency and accuracy in plant operation.

Circumscribed circles up to 130 mm

Machinery:

BYSTRONIC ByTube 130

BYSTRONIC ByTube 130

View gallery

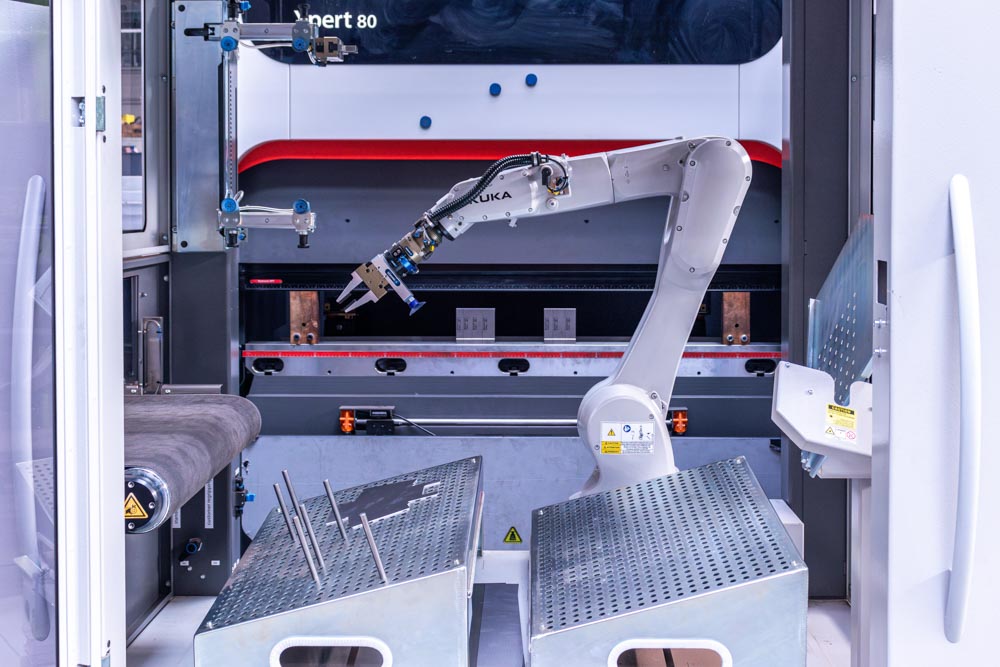

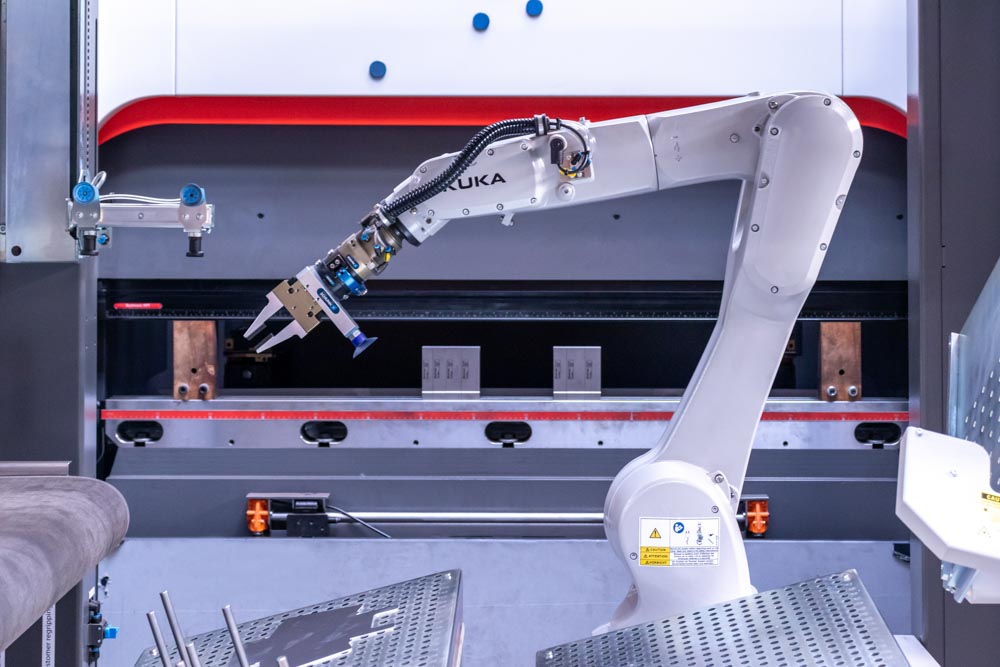

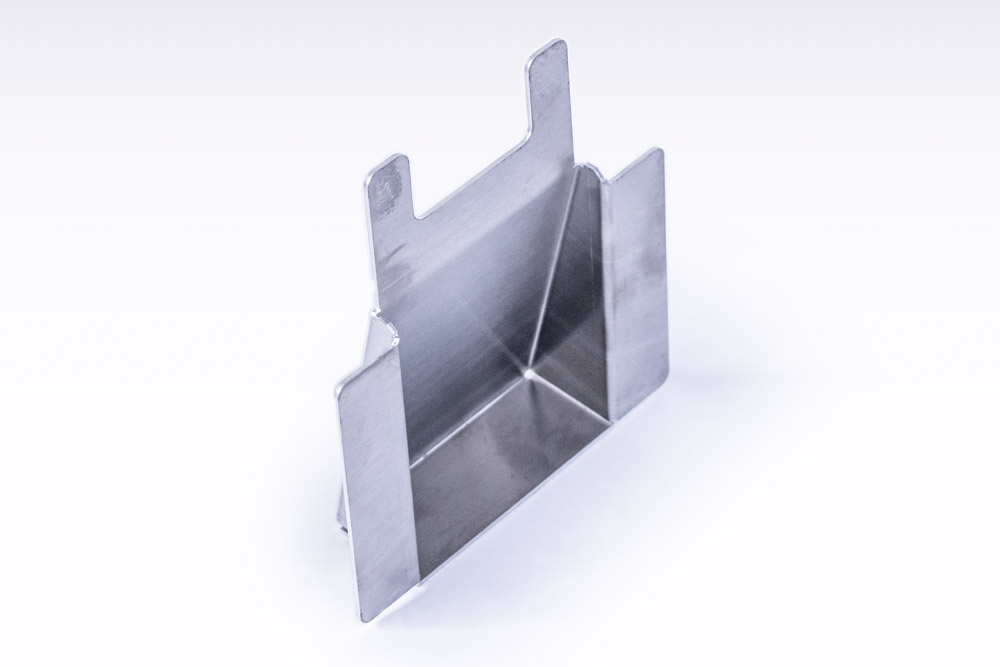

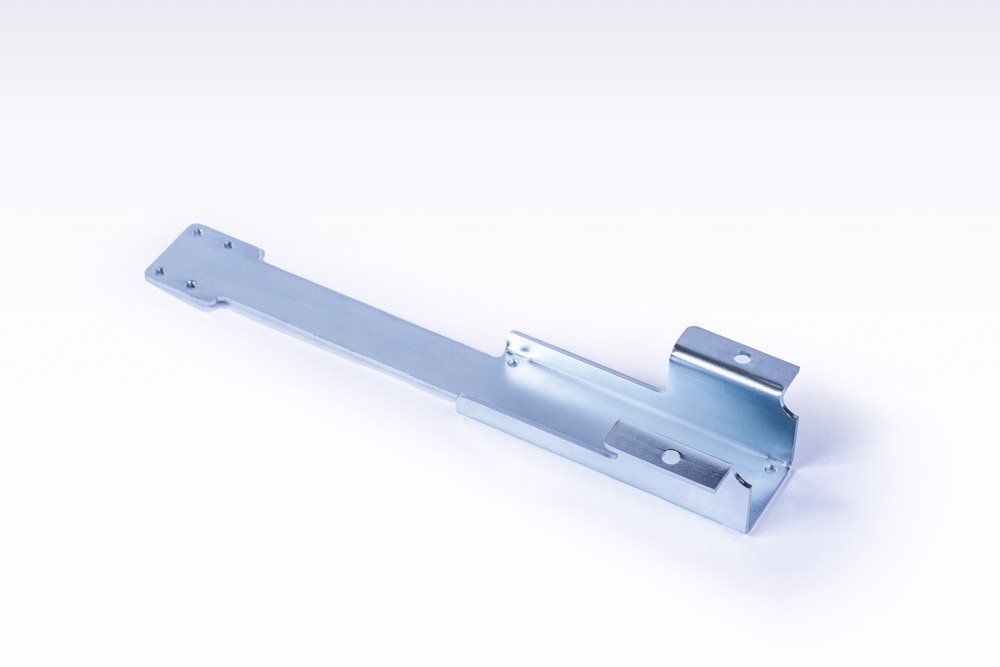

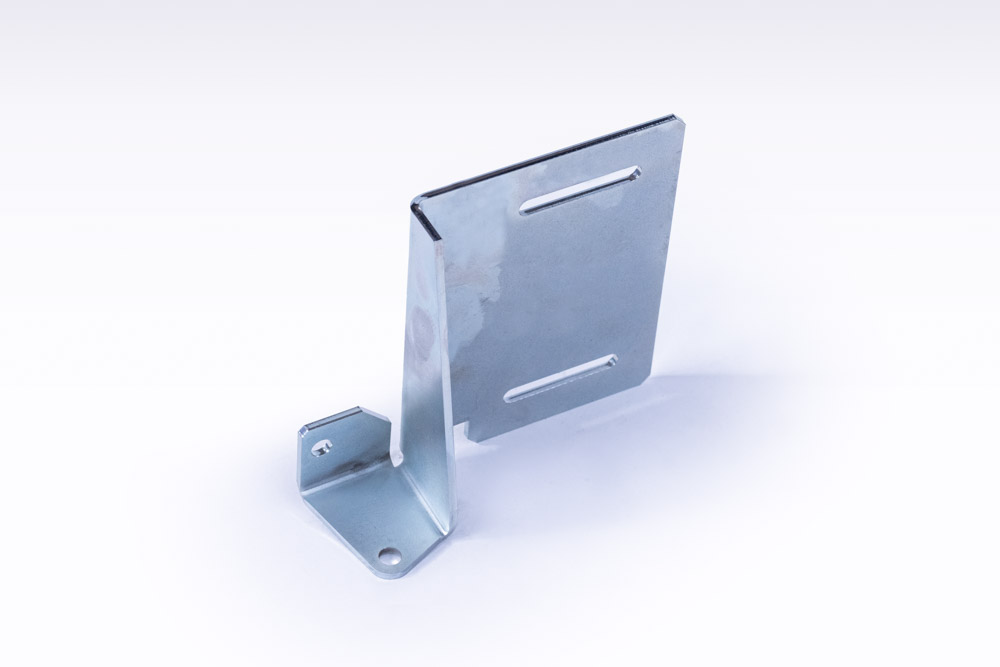

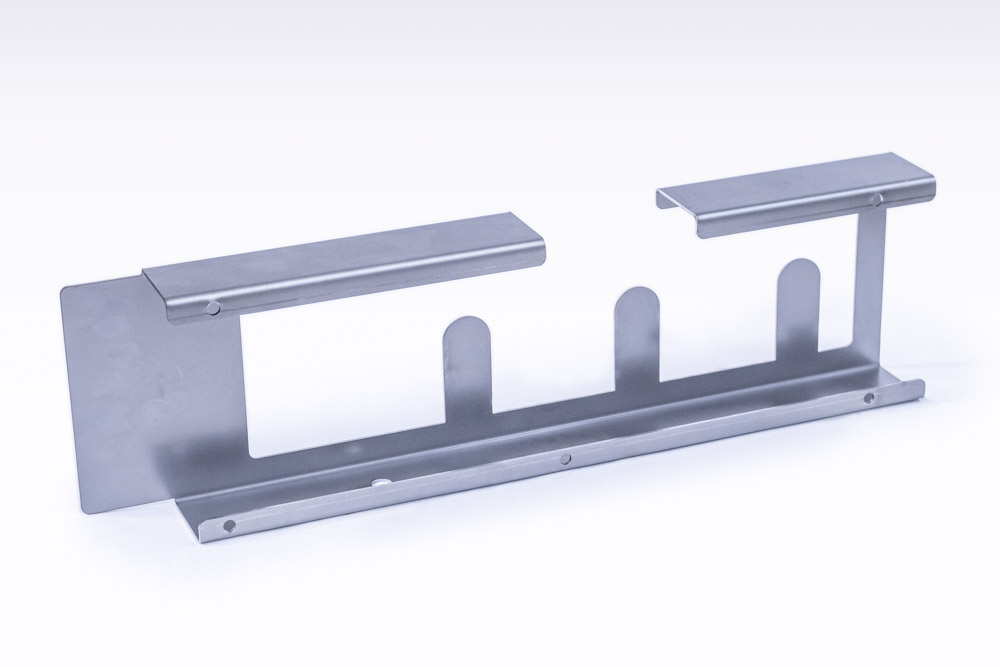

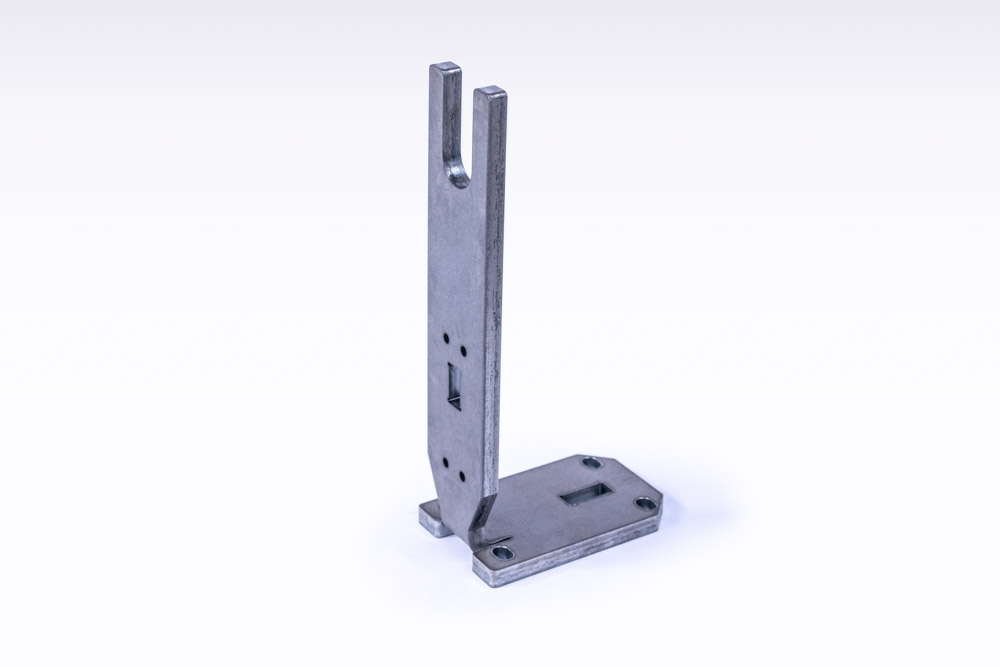

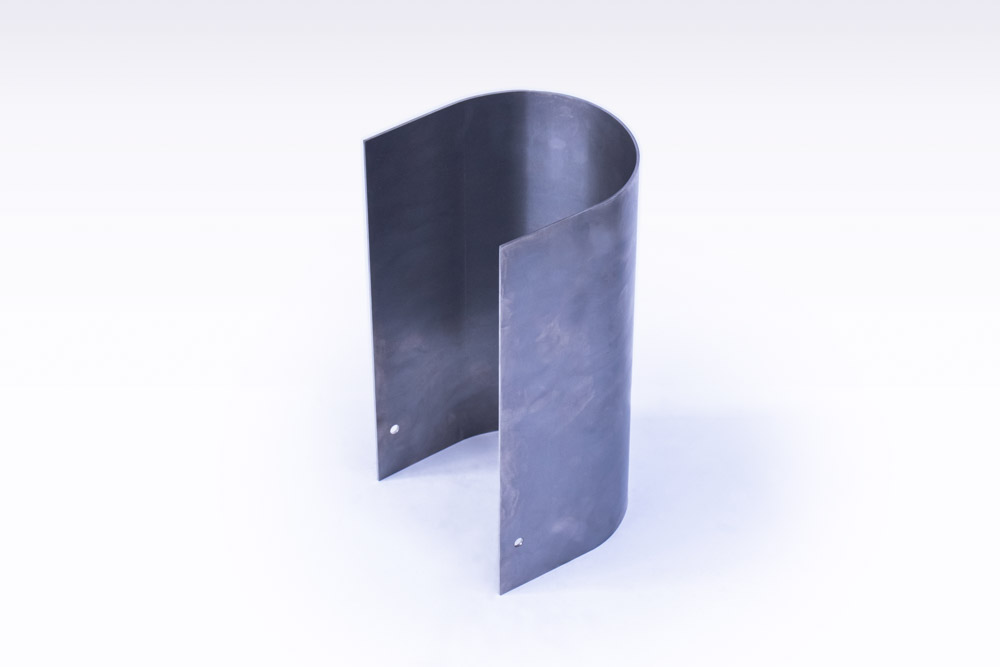

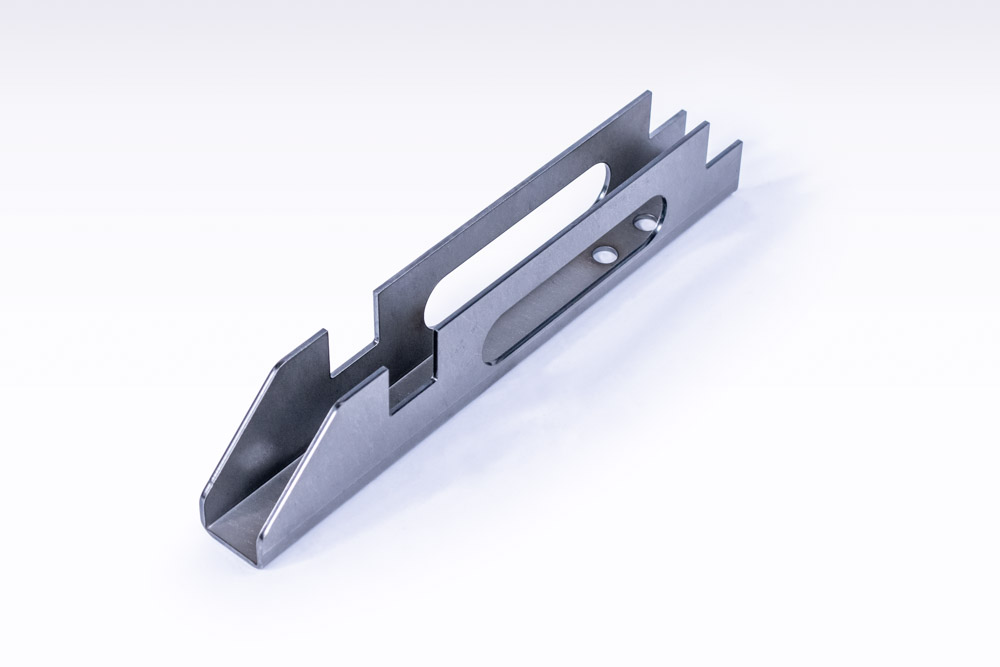

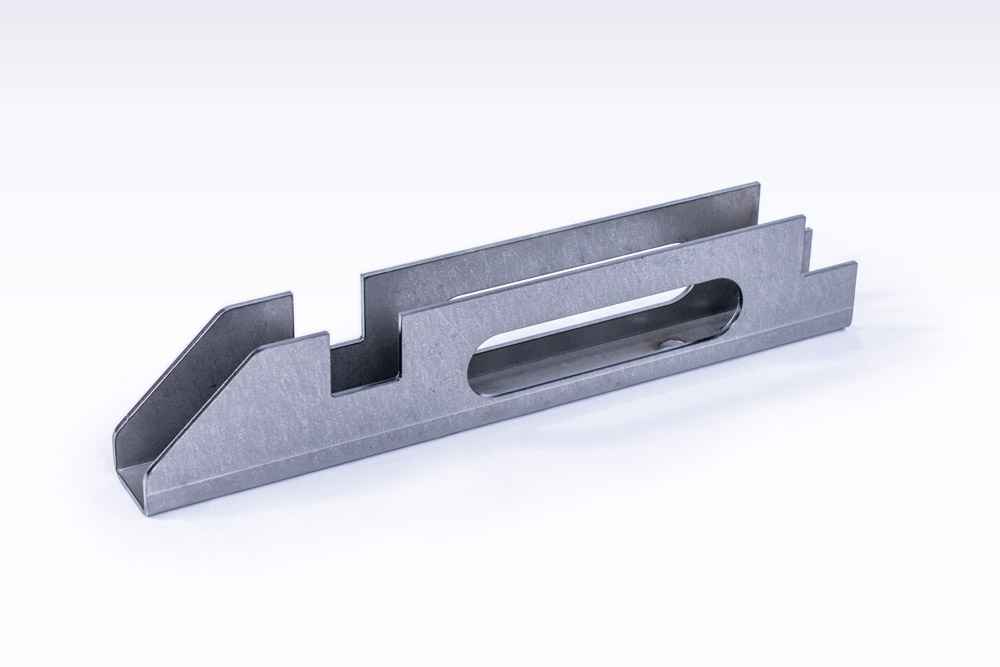

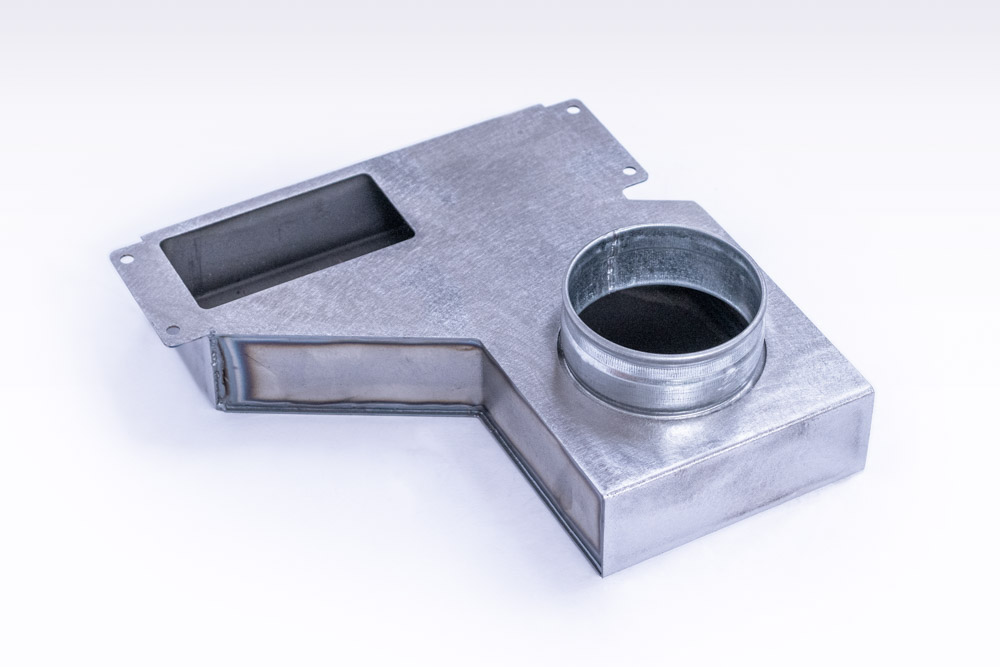

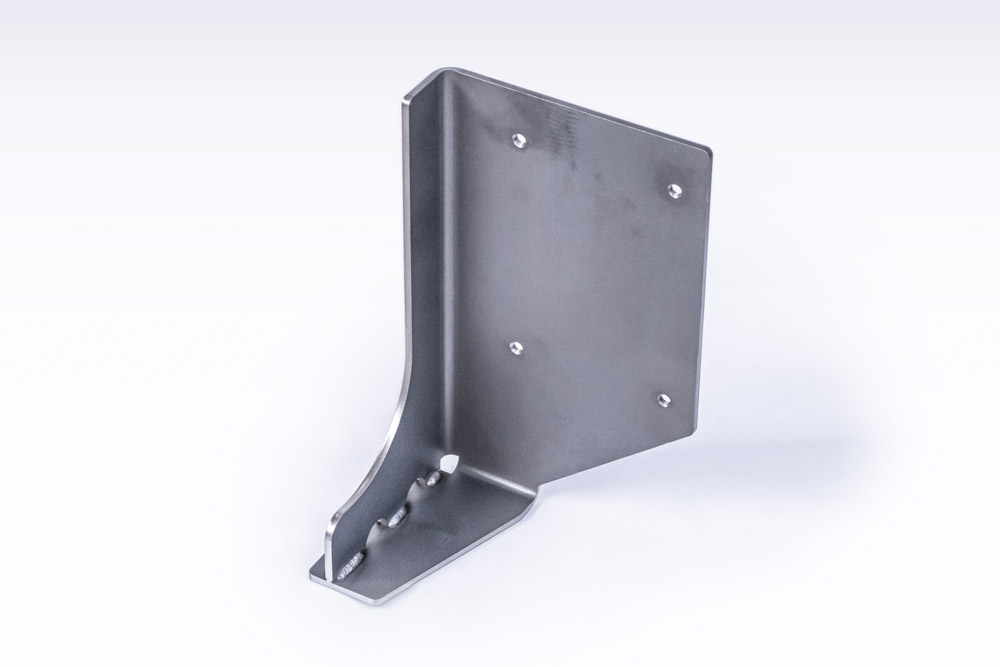

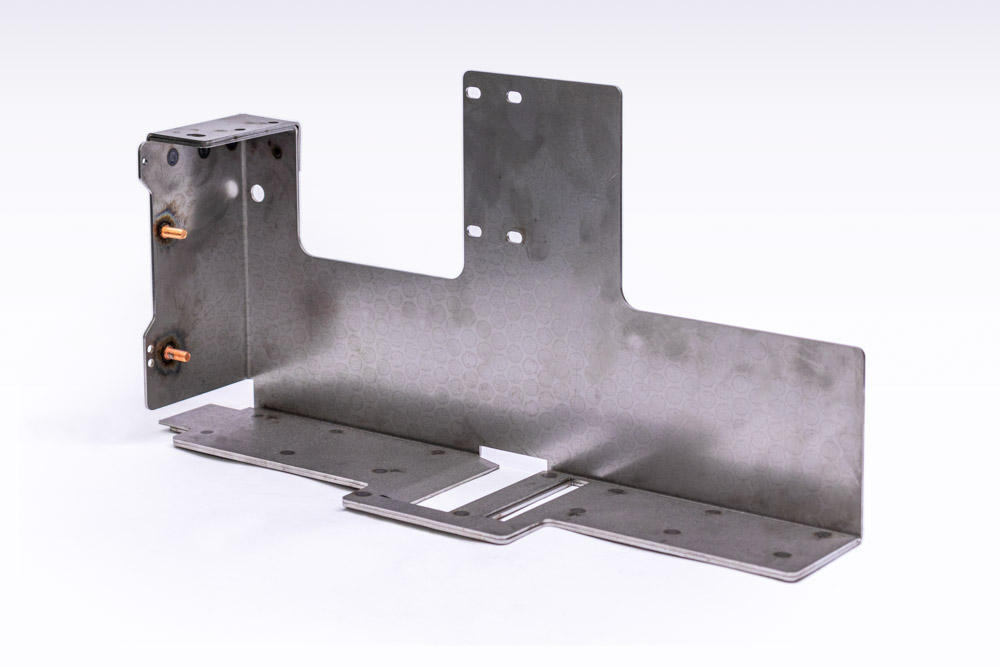

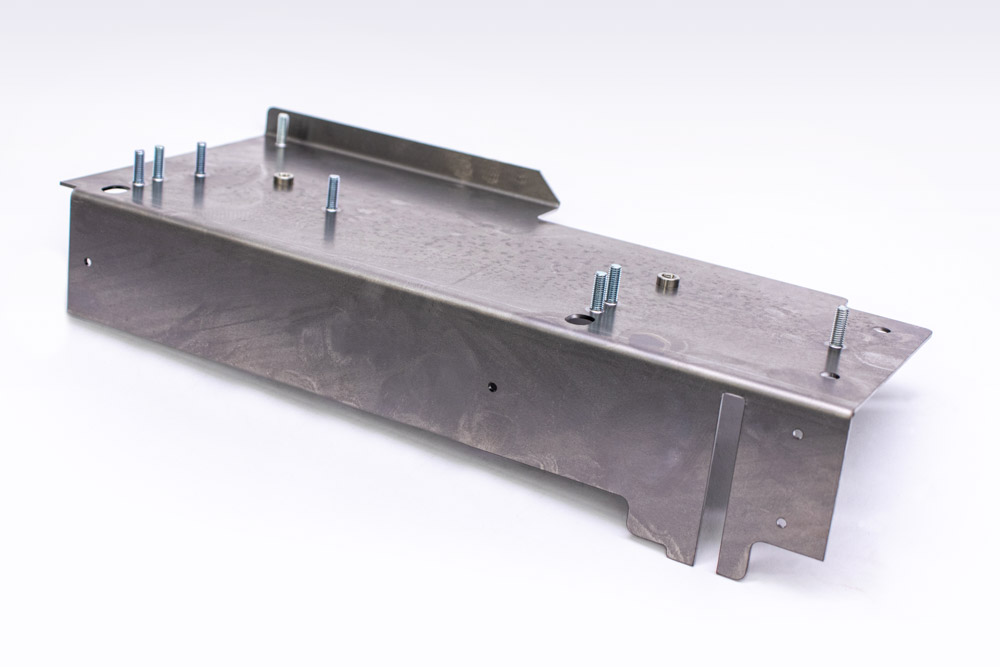

Sheet metal bending

We bend (stainless) steel sheets on CNC bending presses operating in a three-shift regime. A fully automatic robotic bending machine is used for smaller parts of approximately 0.5 × 0.5 × 0.2 m.

Machinery:

SafanDarley E-Brake B100-3100

Safan E-Brake 35-1250

SafanDarley H-Brake Hybrid E-Control 170.42/37

DAVI MCA2019 CNC bending machine

Bystronic Xpert Pro 200

Bystronic robotic bending workstation

SafanDarley E-Brake B100-3100

Safan E-Brake 35-1250

SafanDarley H-Brake Hybrid E-Control 170.42/37

DAVI MCA2019 CNC bending machine

Bystronic Xpert Pro 200

Bystronic robotic bending workstation

View gallery

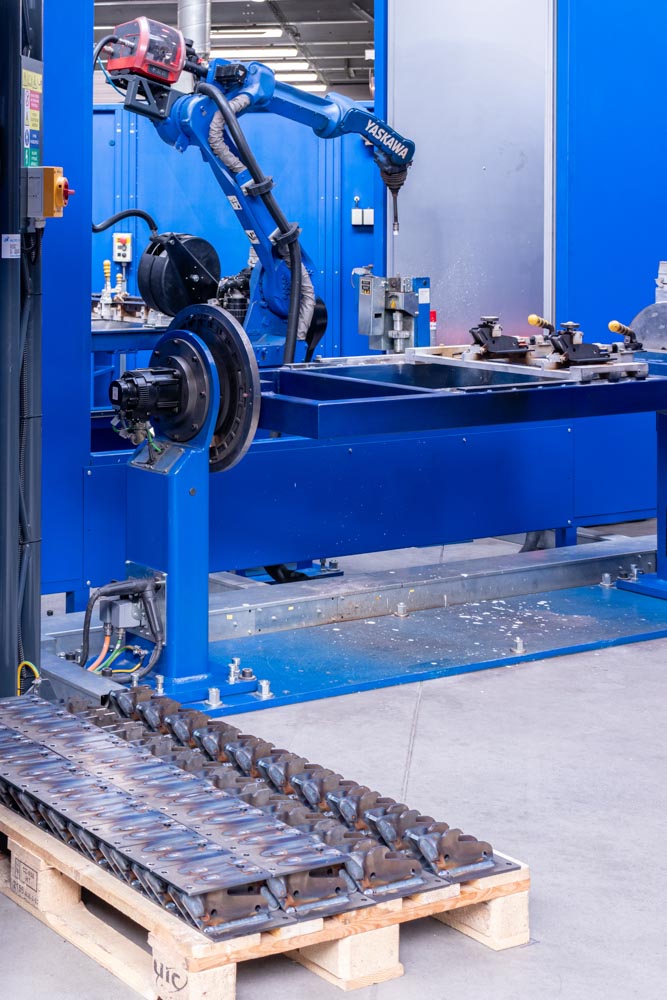

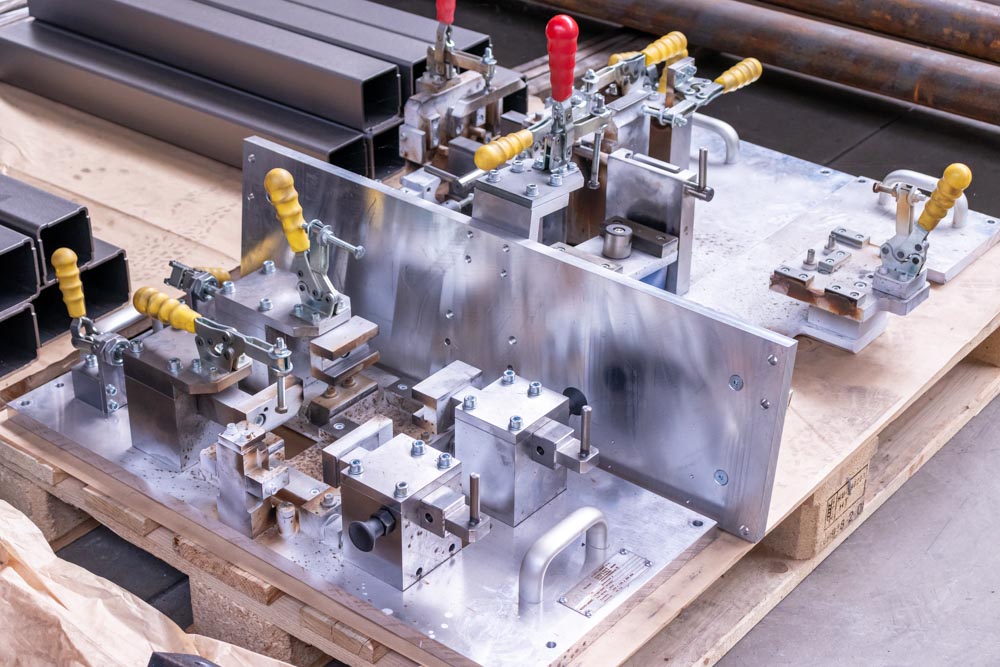

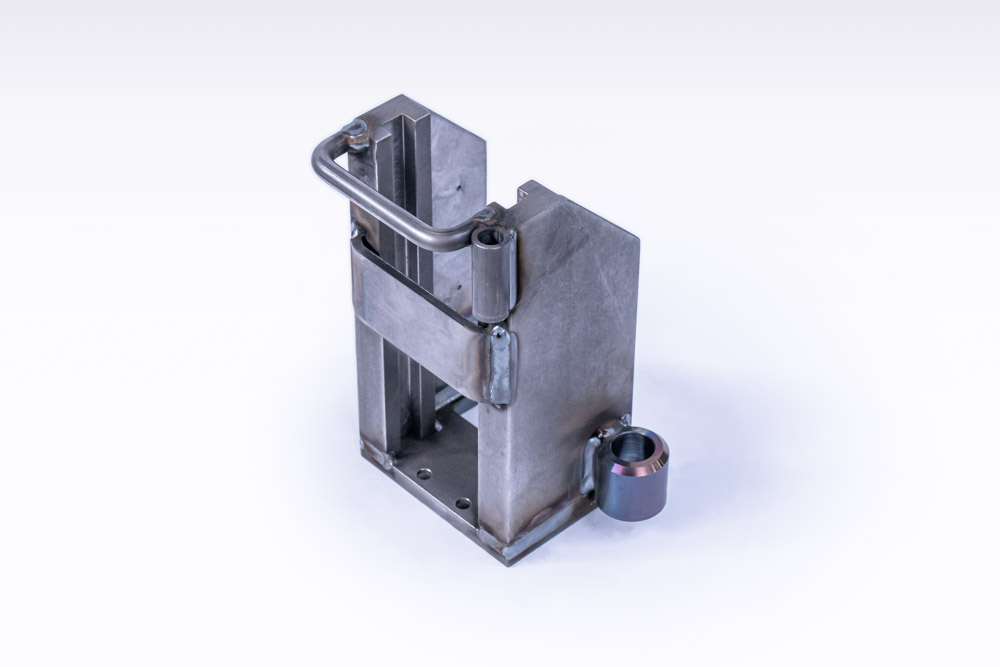

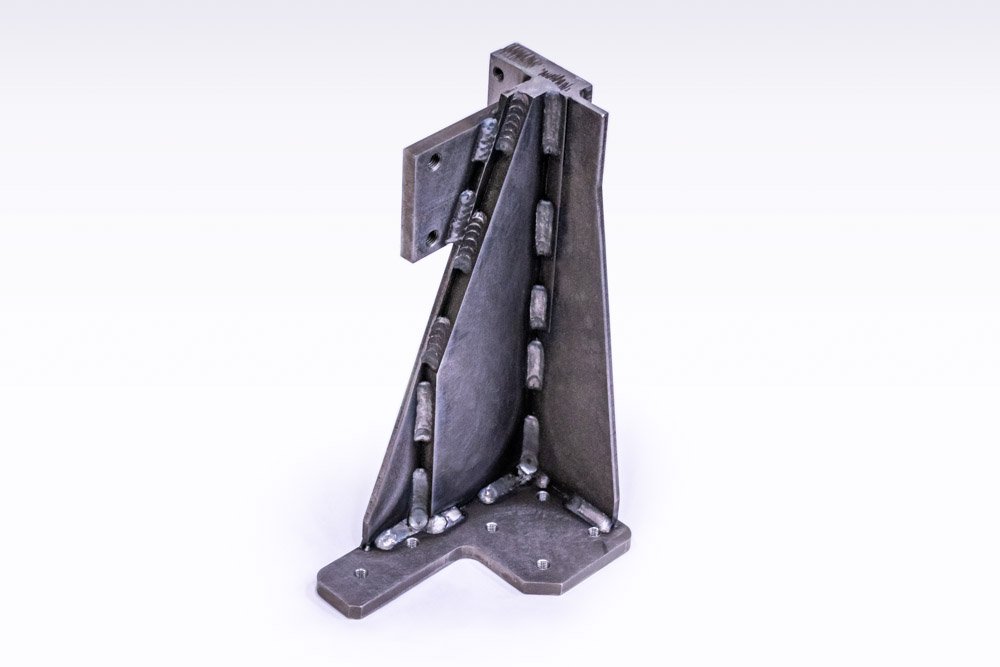

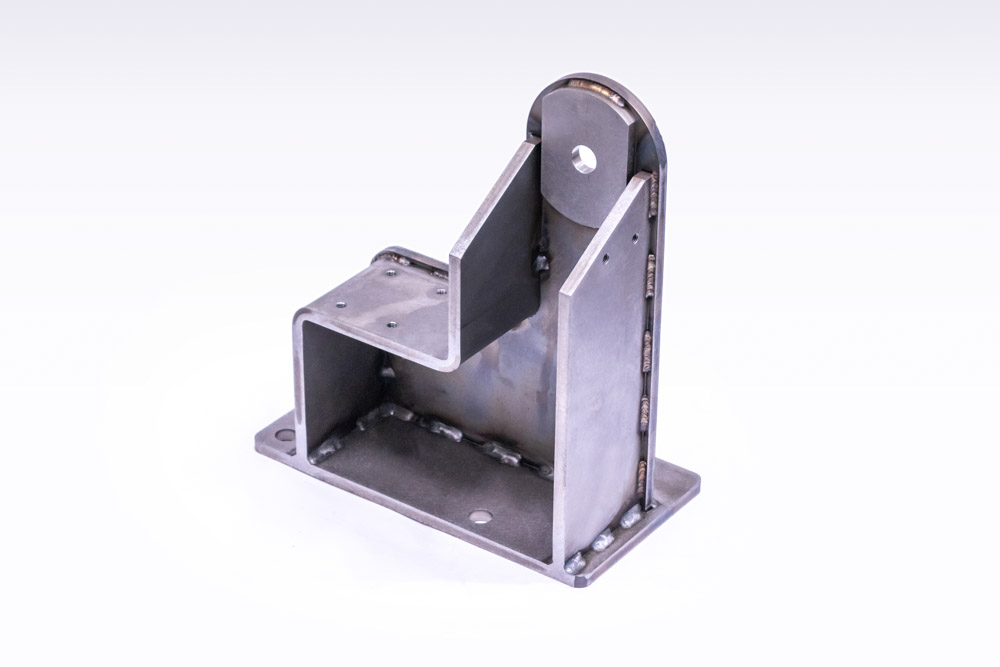

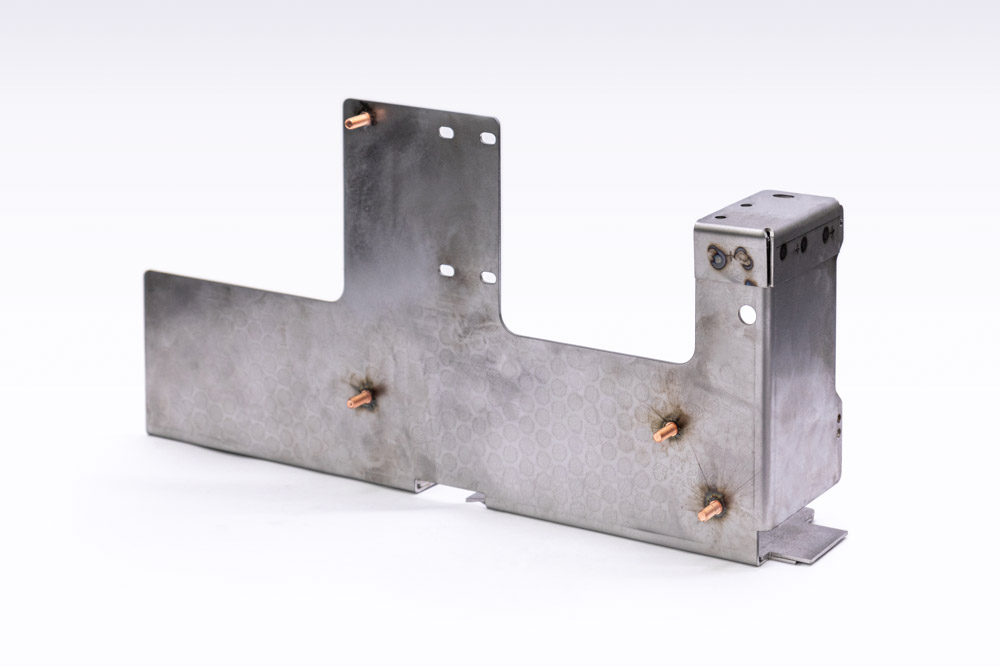

Welding

We provide our customers with comprehensive services including component assembly using advanced welding technologies.

MIG

TIG

Welding robots at three separate workplaces

TIG

Welding robots at three separate workplaces

View gallery

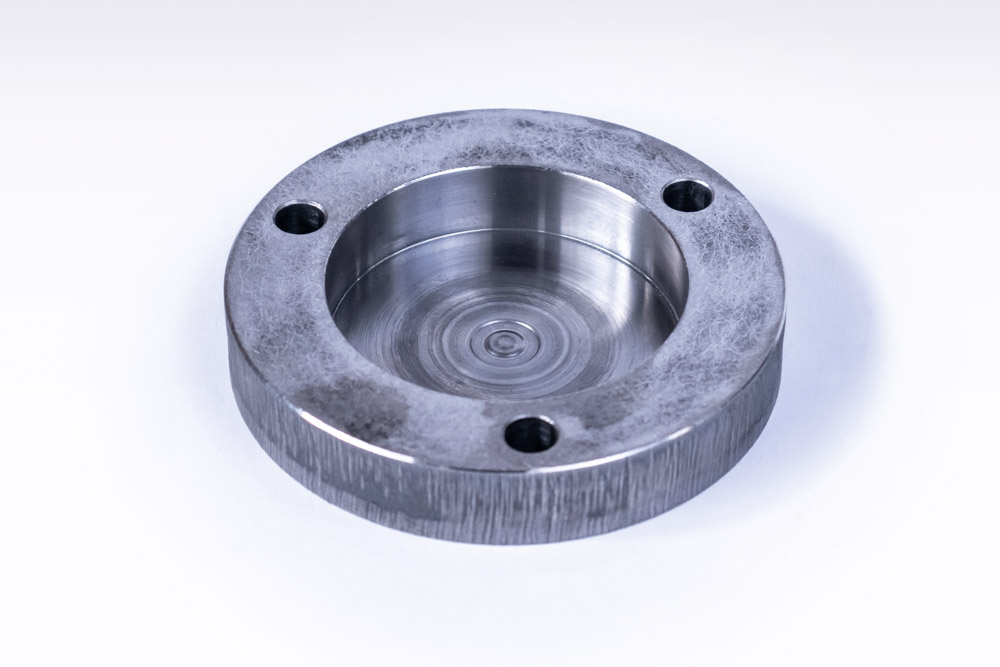

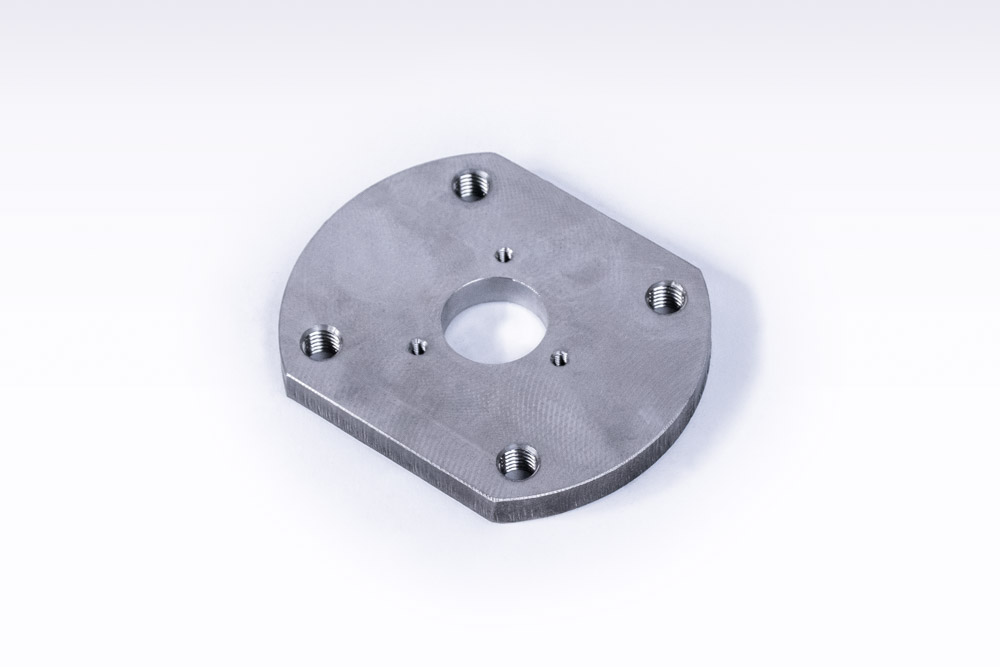

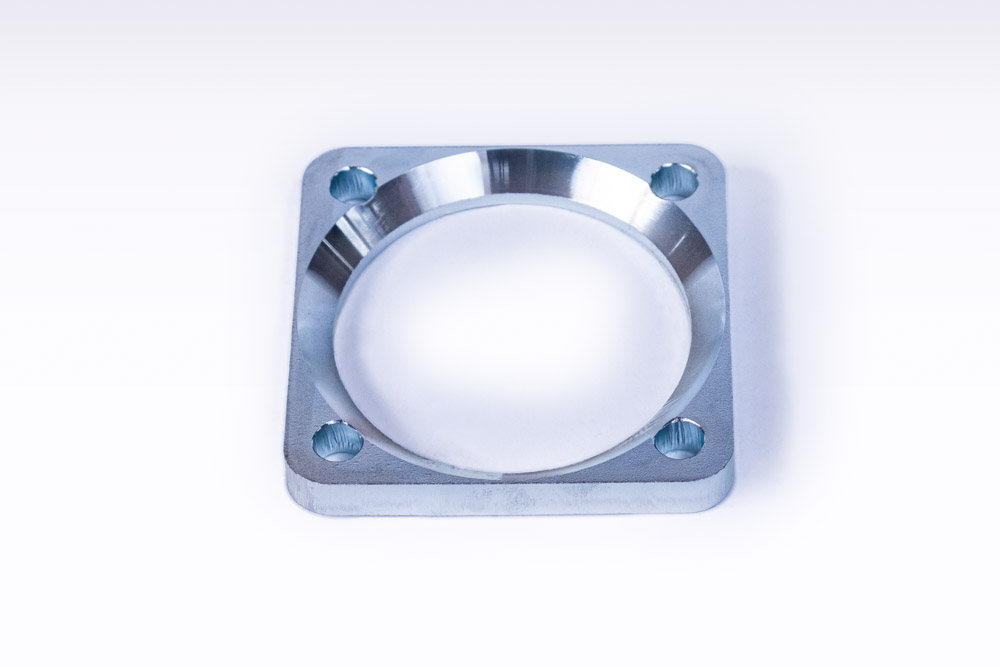

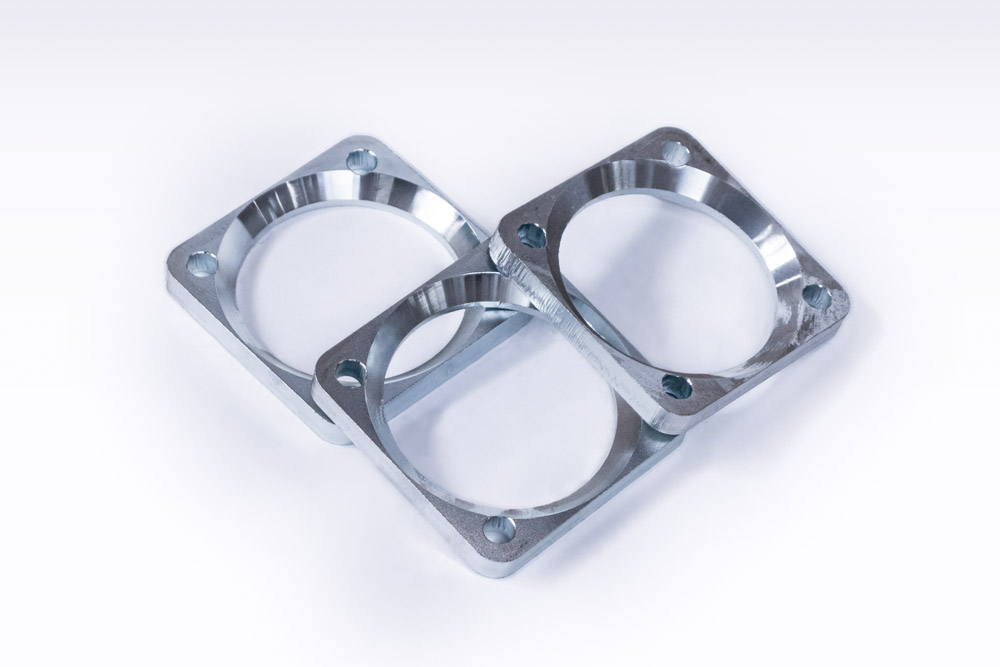

Machining

As part of our comprehensive services, we also offer our customers chip machining on conventional and CNC machines, including robotic grinding.

Machinery:

HASS ST-25 CNC lathe

HASS TL-2 CNC lathe

HASS DS-30Y CNC lathe

HASS VF-4 CNC milling machine

HASS SMIMIMILL 2 CNC milling machine

HASS UMC-1000SS CNC milling machine

KALTENBACH KKS 461 NA CNC mitre saw

HASS ST-25 CNC lathe

HASS TL-2 CNC lathe

HASS DS-30Y CNC lathe

HASS VF-4 CNC milling machine

HASS SMIMIMILL 2 CNC milling machine

HASS UMC-1000SS CNC milling machine

KALTENBACH KKS 461 NA CNC mitre saw

View gallery

Surface treatment

We treat metal part surfaces using the technologies listed below. In addition to traditional manual work, we have invested in a modern automatic workplace equipped with a robot for grinding exposed surfaces.

Grinding

Graining

Sandblasting

Grinding robot

Graining

Sandblasting

Grinding robot

View gallery

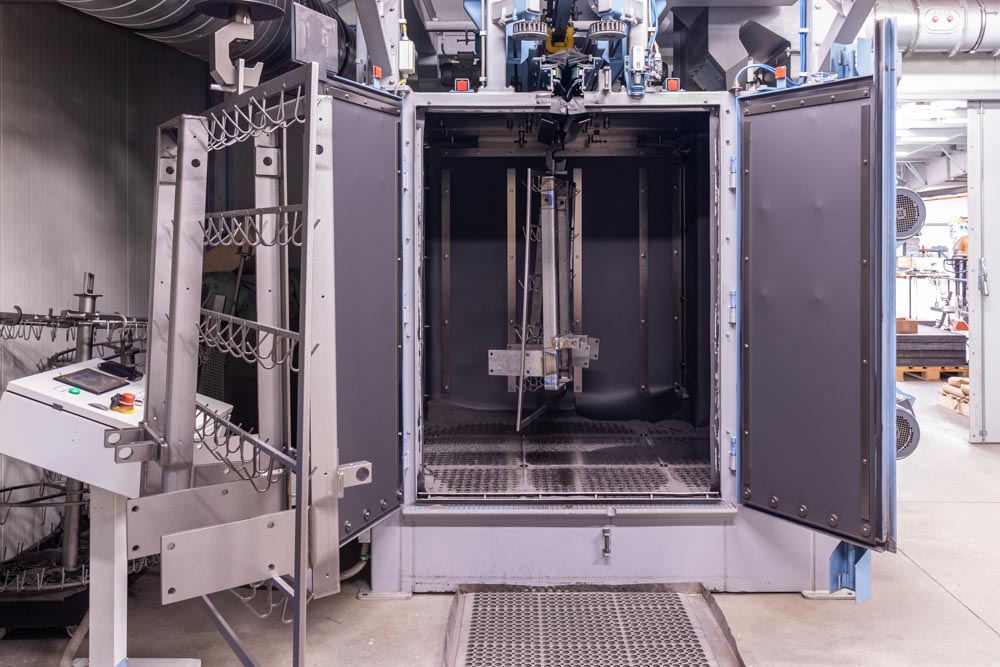

Powder coating

The continuous line is equipped with a powder coating system for surface finishing. Pretreatment of parts by phosphating and passivation is a matter of course.

TRIBO

Statics

Statics

View gallery

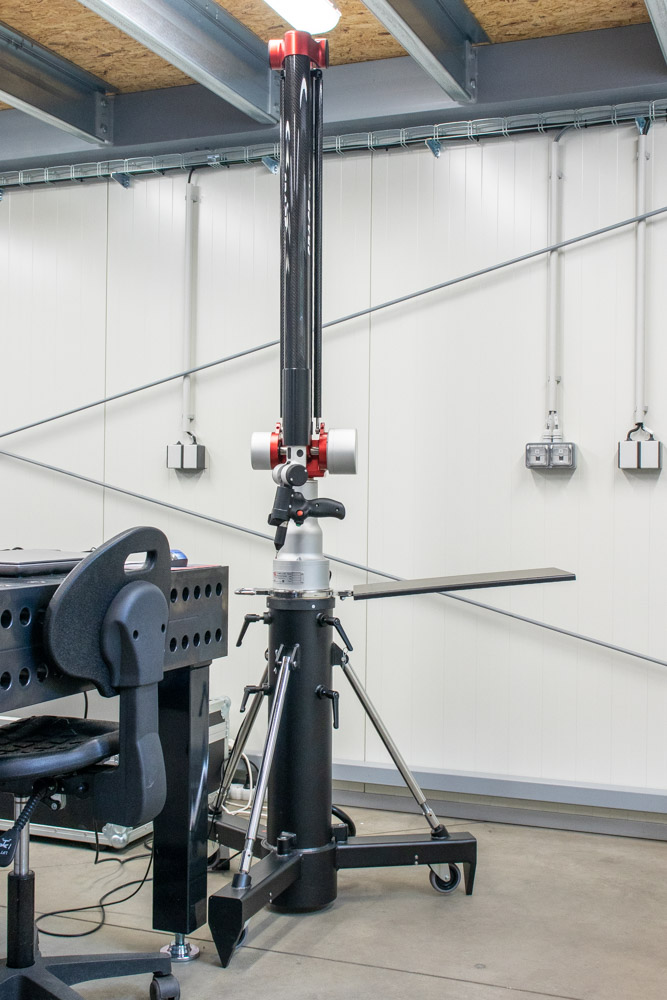

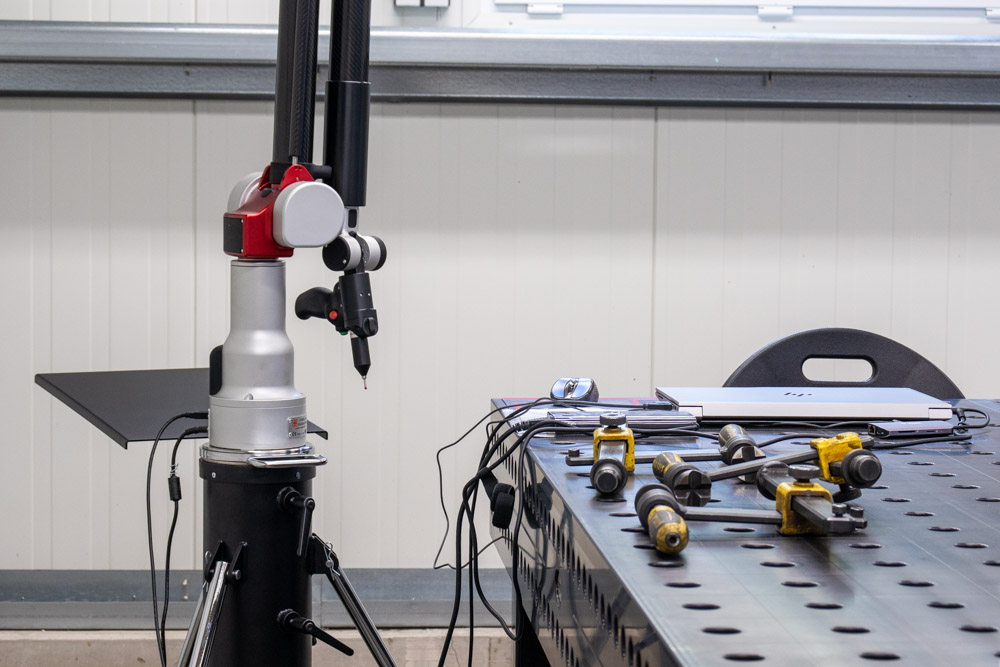

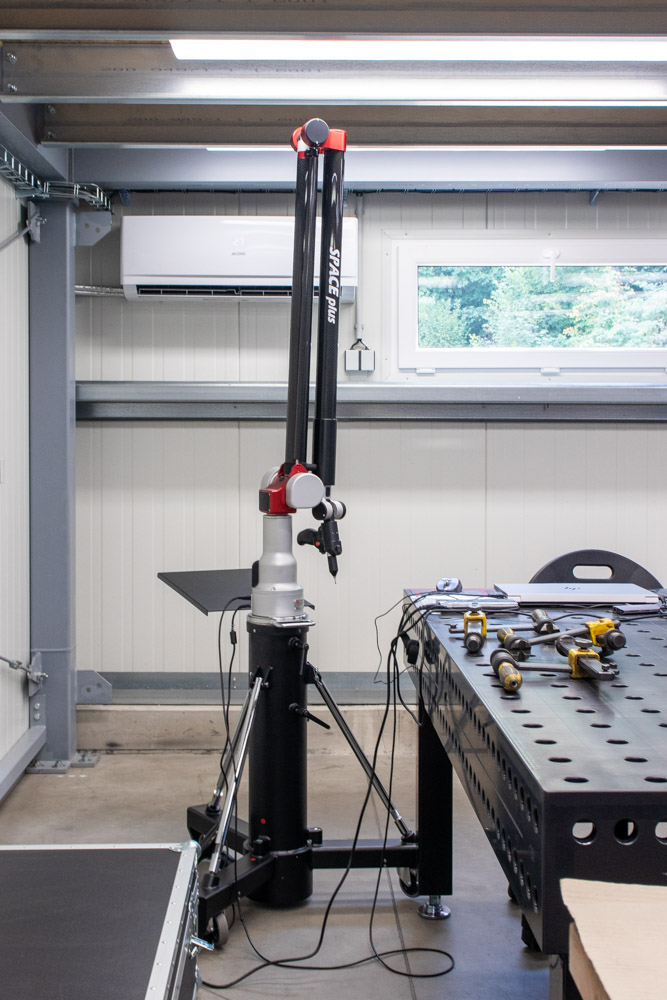

Quality control

Quality control is a natural part of the production chain. We have a specialised workplace for this purpose. This state-of-the-art workstation is equipped with calibrated gauges including a Tomelleri portable 3D measuring arm with a ≤ 4-metre measuring range for efficient and accurate inspection of large assemblies. The dimensional accuracy and surface finish inspection occurs in an air-conditioned area. The observed values are recorded in measurement reports that are included with the production documentation.

Tomelleri

View gallery